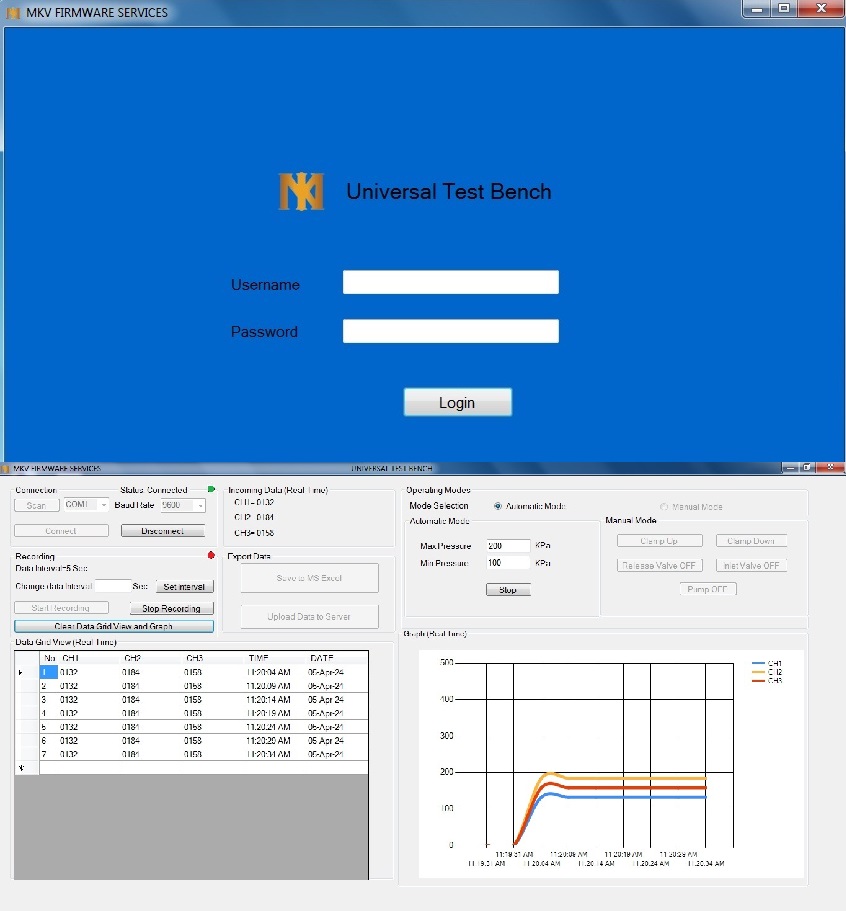

Indigenous SCADA Software for Process Control and Data Acquisition at Cloud Server

SCADA Software can be used to monitor and control a process remotely.

This SCADA software can be used with any PLC and microcontroller based system.

Three level protection has been provided.Admin, Engineer and User can access only those segments which are dedicated for them.

There are two modes of operation: Automatic mode and Manual mode/Diagnostic mode.

Settings option has been provided to set parameters as per requirement.All parameters are set prior to operating/starting the process in Automatic mode.

Real Time Data can be stored at desired interval. Data interval can be set as per requirement.

The data can be stored in the form of pdf or excel data sheet at local memory as well as cloud server.

HMIMC-32B, IoT based system with bilingual audio-visual user interface for process control

Modes of operation: The entire system can be operated in two modes; Fully Automatic Mode and Manual Mode.

User Interface: Bilingual audio visual interface with 7 inch touch enabled screen has been provided to set parameters for automatic operation of any process. Users can operate the device using Hindi / English language as per their convenience.

Communication: 4G enabled GSM Module compatible to any 4G enabled SIM for remote monitoring / operation of process using Mobile Phones.

Data Acquisition at Cloud Server: IoT (Internet of Things) based product for data acquisition at cloud server.

Embedded System: 32 bit microcontroller based product with customized firmware as per required process automation.

Audio Interface: MODBUS RTU communication based programmable audio device which can annunciate messages for smooth operation of device thereby making the device more user friendly.

Communication: 4G enabled GSM Module compatible to any 4G enabled SIM card has been provided for remote operation and data transfer.

System Accessibility: A customized Mobile App has been provided for monitoring and controlling the process. Also, there will be a PC based customized software to remotely monitor the process and view the real time data.

Data Acquisition: Real time data acquisition can be performed. Data will be saved at cloud server. The same data can be accessed using Mobile App as well as PC based software.

Process Scheduling: If required, user can schedule the process e.g. ON/OFF time of process.

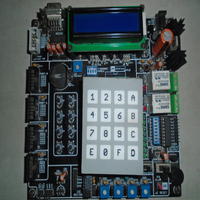

MKV-51-SDK

Universal Development board for microcontrollers of 8051 family and AVR family.

4×4 matrix keypad.

On board Two Line LCD Display (4×20)

L293D 600mA Dual DC motor Driver

ULN2003 500mA driver

RS-232 Interfaces (For direct connection to PC’s Serial port)

Real-Time Clock with Battery Holder

4 Analog Potentiometers connected to ADC

TSOP1738 IR receiver

3V button cell for on chip RTC

On Board Buzzer Interface

MKV-LPC2148-SDK

No separate programmer required (Can be programmed with Flash Magic using on-chip boot loader)

No Separate power adapter required (USB port gives power supply)

Detachable PCB containing LPC2148 Microcontroller.

4×4 matrix keypad.

Wireless module adapter for 2.4GHz ZigBee (Xbee) / Bluetooth / WiFi connectivity

On board 512 bytes of I2C external EEPROM

USB Type B Connector

SD / MMC card holder with SPI interface

10pin(2X5) FRC JTAG connector for Programming and debugging

50 Pin Expansion header for easy access to I/O pins

On board Two Line LCD Display (4×20)

L293D 600mA Dual DC motor Driver

ULN2003 500mA driver

Two RS-232 Interfaces (For direct connection to PC’s Serial port)

Real-Time Clock with Battery Holder

2 Analog Potentiometers connected to ADC

TSOP1738 IR receiver

Reset and Boot loader switches

3V button cell for on chip RTC

On Board Buzzer Interface

Schematics and Application examples in KEIL provided in the documentation CD

Automatic Pump Operator for Home

Fully automatic control of turning ON/OFF of submersible pump.

Dry run protection (if pump is not supplying water or has taken air it will be turned off).

Current overload protection.

Monitoring of water level of tank. Pump will be turned ON automatically when water level is below lower limit and the pump will be turned OFF as soon as water tank is full.

If tank is full, the pump can not be turned ON deliberately.

Operative power requirement: 230V.

Automatic Pump Operator for water supply authorities

Fully automatic control of turning ON/OFF of water supply pump (1phase / 3 phase)

Switching over multiple pump running

Setting water supply time (up to 12 time settings available)

In case of power cut, pump will resume supply for remaining time

SMS alert can be sent to operator / administrator

Retrieval of monthly/ daily log through wireless communication.

Dry run protection (if pump is not supplying water or has taken air it will be turned off)

Current overload protection

Water level of tank (Pump will be turned OFF automatically when tank is full)

Operative power requirement: 230V.

Embedded system based technology (LPC2148)32 bit micro controller.

External memory (EEPROM 4K).

Battery powered real time clock.

4×20 LCD to display total runtime and status of program execution.

4×3 matrix keypad for settings parameters.

RO Controller for Water Treatment Plant

Microcontroller based fully automatic system.

Auto Flushing during start up. Cyclic Flushing

Once Auto Flushing during start up is over, Auto Flushing can be skipped in case of next startup due to power failure.

Dosing starts automatically if TDS value exceeds the limit. Dosing stops as soon as TDS value of purified water lowers to safe limit.

Indication of total volume (in Liter) of purified water.

Fully automatic cyclic cleaning of Micron filters using MPV (Multi Positioning Valve).

Low Pressure Switch, High Pressure Switch

Pump dry running protection

Current Overload Protection

Level of water in Raw Water Tank and Treated Water Tank

Operative power requirement: 230V

32 bit Microcontroller (LPC2148)

External memory (EEPROM 4k)

Battery powered real time clock

4×20 LCD for display of TDS value and current drawn by the pumps

4×3 Matrix Keypad for setting parameters like Current Limit, Flush Time, TDS Limit